Innovation: revolPET® technology

The plastic revolution: revolPET®

With the internationally patented revolPET® technology, we are creating an added value cycle for every form of plastics:

- Multi-layer packaging

- Coloured and opaque materials

- Polyester textiles

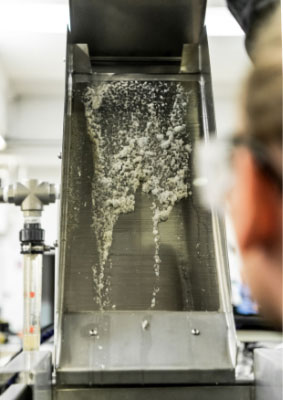

Conventional mechanical recycling methods are only suitable for unmixed polyethylene terephthalate (PET). Our revolPET® technology revolutionises the recycling of PET and polyester waste. It is the first technology to break down PET and polyester into its components - the monomers terephthalic acid (TA) and monoethylene glycol (MEG) - in a continuous process.

Three crucial features characterise revolPET®:

- Continuous selective depolymerisation in less than 1 minute

- Conversion of over 97 percent of PET into its components

- Continuously variable scalability to maximise capacity

The input material can be multi-layer or mixed plastics. Its condition has no influence on the monomers produced. They are the same quality as primary materials and can be re-used for production of all kinds of PET products.

revolPET® is a platform technology that can be used for different input flows: The revolPET® technology has been tested for packaging and textiles.

Cooperations: Science and business

Changing the present together

Cooperation with research institutions provides access to the very latest know-how and a wide range of expertise. Our networks enable us to promote ongoing technology research based on the circular economy concept and resource conservation. Joint acquisition of public funding smooths the way for long-term cooperations and thus for development of innovative and patentable solutions. We have close cooperation with the Institute for Chemical and Thermal Process Engineering at TU Braunschweig.

We incorporate application-specific knowledge through our close cooperation with corporate partners. This strengthens the ongoing development of our innovations moving towards their launch - established and proven technological methods are integrated. This enables us to create the required process reliability for our customers and to reduce the installation and operating risk.

Research & development

R&D: Economically efficient and environmentally friendly

Research & development is at the heart of our technology solutions that address the urgent needs of the market. We believe it is essential that, as well as technical excellence, our solutions delivery economic success and an environmental advantage over existing solutions. Teams from science, engineering and economics work together to achieve the objectives we seek for our customers.

In parallel to the technical developments, the results are continuously being assessed against market requirements, while the environmental impacts are analysed and evaluated. Our aim is to create innovative, patentable and competitive developments that will quickly carve out a successful position in the market.